PPM 300 Emergency genset controller

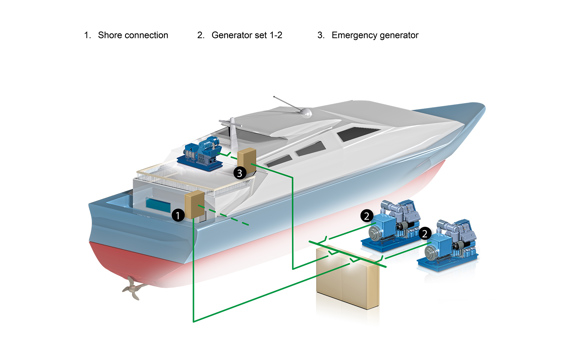

The PPM 300 Emergency genset controller controls and protects an emergency genset (both the engine and the generator), the generator breaker, and the emergency busbar tie breaker. Designed to deliver reliable performance in emergency situations, the controller by default starts the emergency generator when there is no voltage on the busbar, and it includes a test function that makes regular emergency genset testing easier.

The PPM 300 Emergency genset controller allows harbour operation so that the genset can be used as the ship generator when in harbour. Each Emergency genset controller can connect up to three non-essential load groups.

Part of the versatile PPM 300 range

The PPM 300 Emergency genset controller is part of the DEIF PPM 300 range of versatile controllers with built-in multi-master power management features. The range offers variants designed for a wide range of marine and offshore applications –from generator control and protection to engineered power management solutions developed for generators, battery energy storage, shore connections, and bus tie breakers. For general information about the PPM 300 range, see the PPM 300 main page.

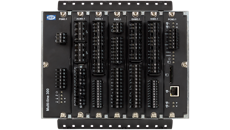

Highly customisable architecture

All PPM 300 variants can be specified with 4 or 7 I/O module slots. The modules provide voltage and current measurement, I/O, engine control, governor and AVR functions, and communication. Three modules are mandatory, but you can use the remaining 1 or 4 slots to customise the controller by adding modules or leave them empty. In addition, you can add up to 9 expansion racks to a single PPM 300 to get up to 58 free module slots (up to 4 in the base rack and up to 6 in each expansion rack).

Unique ANSI 87G differential protection

With the optional ACM3.2 module, you can add ANSI 87G differential protection for generators. The module measures phase currents on the consumer and neutral sides of a generator in order to detect phase-to-phase faults or phase-to-earth faults in earthed generator systems. With this unique feature, you can design reliable and safe power systems without external differential protection devices.

For a full list of modules, see the Modules tab.

Recommended I/O modules

Slot 1 | Slot 2 | Slot 3 | Slot 4 | Slot 5 | Slot 6 | Slot 7 |

PSM3.1 | ACM3.1 | IOM3.1 | EIM3.1 | GAM3.1 | Blind module | PCM3.1 |

The table shows a 7-slot rack, but the controller is also available with a 4-slot rack. Modules PSM3.1, ACM3.1, and PCM3.1 are mandatory. If you add expansion module racks, each expansion rack must contain a PSM3.2 power supply module but does not need to contain other modules.

Other PPM 300 variants

Read more

Product videos

Products

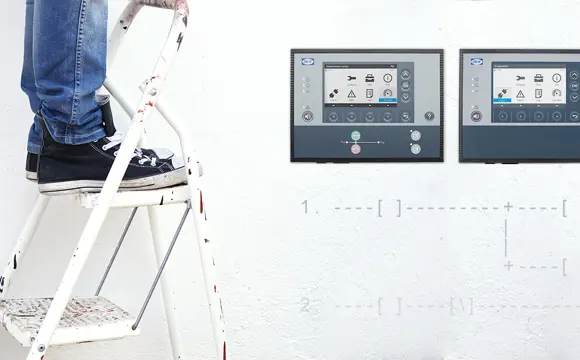

Installing the display unit (DU 300)

Introduction to the display unit (DU 300)

Introduction to the PPM 300 controller rack

Protection and Power Management (PPM 300)

Unboxing the PPM 300

Tutorials

Installing the Multi-line 300 controller rack

Cases

Ferry saves 30 % on fuel consumption

Protection & power management PPM 300 PPM 300

- Synchronization

- Marine certified Power Management - ABP: Advanced blackout prevention (32dg)

- PLC logic

- Engine and Generator protection

- Engine CANbus

- Rear mount

- Flexible Hardware

- Additional I/O racks (9 racks)

- Ethernet Ring connection for Power management

- Redundant breaker feedback

- Colour Display

- Emulation

- Marine approval

- Heavy consumer

- Fast load reduction

- Fuel optimisation

Generator protection unit GPU 300

- Comprehensive generator/busbar protection

- Smart synchronization check

- Supervision

- High resolution 5" colour graphic display with push-buttons

- Flexible and modular input/output with metal rack

- Plug & play, auto-configure I/O modules and network

- Integrated 5 × RJ45 ports with auto-detected multi-function

- Access to all connected units in one point

- Context-sensitive help in the controller display unit

- Event and alarm log, with real-time clock

- Pre-defined control settings

- User-friendly logic configuration tool, based on ladder logic and function blocks with monitor operation

- Password-protected, with customisable permission levels

- 3-phase AC measurement, up to 690 V AC directly, class 0.5

- Easy-to-use PC tool (PICUS)

- Advanced alarm handling with latch and shelve possible

Advanced graphical interface AGI 400

- Wide screen format

- True glass front

- Capacitive touch screen

- Multi-touch and Gestures

- Robust aluminium housing

- SD card slot for easy storage and updating

- USB hosts for printers, accessories, data storage and updating

- Dimmable LED backlight

- Web server for remote access from i.e. mobile devices

- 3 Ethernet ports with integrated switch

- Serial communication (RS-232, RS-422 and RS-485)

- Wide range of support for industrial protocols

- OPC UA Server and Client

- JAVA scripting

- CODESYS V3 (optional)

- Powerful ARM Cortex-A9 processor

- Plug-in module for CANbus (CANopen/J1939)

- Wide operating temperature -20°C to +60°C

- Marine certifications

- Certified for hazardous environments

- Available in 7", 10", 15" and 21" sizes